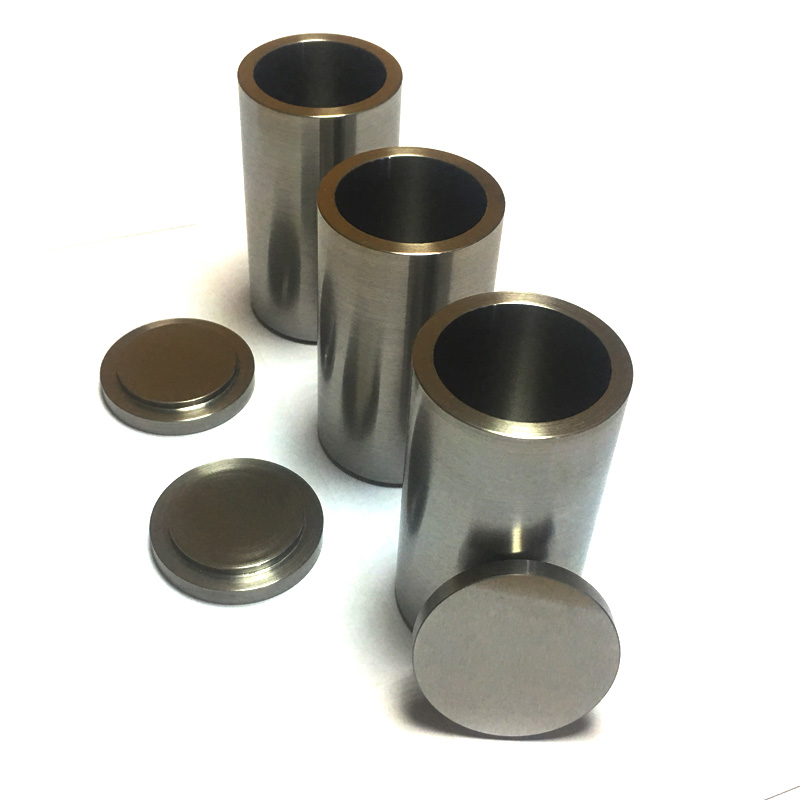

99.95% tungsten crucible for industry smelting

- Product ID: 3148

- Hits: 339

- Company: Baoji hanz metal material Co.,Ltd.

- Keywords: tungsten crucible / 99.95% tungsten crucible / tungsten crucible for industry smelting

- Inquiry Favorite

Five Advantages Of Products

- The chemical content of mateial accord with the national quality control standard, and special processing technology makes our products more competitive advantage.

- Our company can produce crucibles in various shapes, including round mouth crucible, taper crucible, ellipse crucible and bottomless crucible;

- We can provide two kinds of molybdenum crucibles according to different processing methods: Sintering products with density ranges from 9.8g/cc to 10g/cc; Forging products with 10.2g/cc density.

- Customer specific furnace components and fixtures for high temperature furnaces are uniquely designed .

- Tungsten crucible used for sapphire growth furnace, rare earth metals smelting , quartz glass smelting ,heating elements for induction furnaces ,high temperature container

Product Details

Description:

According to different processing methods, tungsten crucibles for vacuum coating can be mainly divided into sintered molding, press molding, spinning molding, turning forming and welding forming. Turning forming is mainly applied.We recommend the working temperature of the tungsten crucible for vacuum coating should be controlled below 2600℃.We can produce tungsten crucible for vacuum coating according to the customer drawing.

1) Purity: 99.95% min.

2) Sintering tungsten crucible

Density: 18.0 - 18.5 g/cm3

Working temperature: 2000- 2600 Dc

Diameter: 100 - 500mm (max.)

Specification according your requirement custom.

3) Forging tungsten crucible

Density: 18.5 - 19.35 g/cm3

Working temperature: 2000- 2600Dc

Diameter: 18 - 150mm (max.)

Specification according your requirement custom.

Features:

1.Tungsten crucible for vacuum coating is mainly used as containers and heating element for evaporation coating machine in optical glasses and spectacles field; high.

2.It has great strength under high temperature, anti-friction corrosion resistance.

3.It also possesses high thermal conductivity, thermal expansion coefficient and good harden ability.

Application:

1.Tungsten crucible for vacuum coating products are widely used for smelting of rare-earth, quartz glass, electronic spraying, crystal growth and other industries.

2. Generally, sintered tungsten crucible is large while the forged one is small; the wall of rolled tungsten crucible is thin; welded tungsten crucible is cost-effective but owns inferior intensity.

3.Tungsten crucible under turning forming is denser than sintered one.

Inquiry

2026 Baoji hanz metal material Co.,Ltd. All Rights Reserved.